Polymerics Chemical Blending

Polymerics is your personal compound and chemical supplier!

We pride ourselves on experience, technology, and personal response.

Polymerics operates a state of the art chemical blending facility in Kent, Ohio.

We define a "cure blend" as a mixture of waxes, antioxidants, accelerators, and other rubber chemicals that would traditionally be weighed at a compounder's station. Polymerics takes your custom requirements for a given batch of mixed rubber, blends the raw materials, and then accurately pre-weighs the chemicals into a low melt inclusion bag. Instead of weighing at your facility, the operator simply adds a Polymerics bag into the rubber batch.

- There are MANY advantages to using chemical cure blends! Among these are:

- Batch to batch consistency is greatly improved due to precision weighing and no fly loss of powders

- Reduces raw material inventory and saves warehouse space by reducing multiple items to one

- Reduces housekeeping issues such as "chemical dusting" and chemicals in waste water

- Our "state-of-the-art" computer weigh out system eliminates operator error and provides 100% traceability

- Eliminates production down time due to incorrect raw material weigh outs

- Reduces scrap – root cause analysis

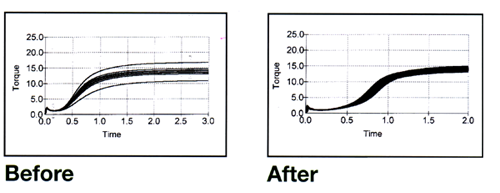

The charts below show an example of improvements realized by the use of Polymerics preweighs:

Polymerics chemical blends are 100% traceable. We bar code all incoming raw materials. Each ingredient is scanned with a bar code reader by the operator. Our software checks the raw material code versus your formulation and also verifies shelf life. The operator must weigh each ingredient within highly accurate limits allowed by the operating system. Every cure bag is coded by inkjet with a unique code. In the event that you find a stray bag in your plant, we can tell you the content along with the lot number of every chemical in the bag and its production date. Our chemical blends are available in custom packaging, sizes, weights and also bulk.

FDA and medical grade compliant chemical blends are available.

- Benefits

- Increased control

- Tighter consistency

- Modulus

- Tensile

- Cure Rates

- Safe Material Handling

- Features

- 40+ years experience

- Accurate system used for all pre-weigh bags (+/-1%)

- Bar coded lot control

- Raw material weigh-out (+/-1%)

- In-process testing on each batch

- Controlled batch mixing capabilities

- Samples retained for 6 months

- Documentation retained for 7 years

- SPC data

- Complete traceability and record keeping

- "Bulk Pak" in Gaylord cartons

- 60 lb. to 800 lb. batch mixing capabilities

- Individually marked bags to customer specifications

- Testing on all incoming materials