Polymerics Custom Mixing Overview

Polymerics is your personal compound and chemical supplier!

We pride ourselves on experience, technology, and personal response.

We operate two internal mixer lines at our facility in Cuyahoga Falls, Ohio.

Polymers

We mix natural rubber (NR), EPDM, nitrile rubber (NBR), styrene-butadiene (SBR), polychloroprene or Neoprene (CR), "Hypalon®" (CSM), polybutadiene (BR), isoporene (IR), butyl (IIR),millable urethane (we do not mix silicones or FKM).

Black Line

Our #9 Banbury is dedicated to black stocks. Our average batch size is 325 lbs. The FACTS system is installed and provides mixing monitoring and control. We can add optional straining at various mesh sizes.

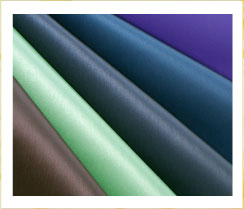

Color Line

We also operate an F-80 dedicated color only line with an average batch size of 150 lbs. This line will also include the FACTS mixing control system. We can add optional straining at various mesh sizes. Our color mixing room has positive pressured, filtered air flow to insure that no carbon black dust reaches our color mixing area.

Mill Mixing

We have a dedicated 60 inch mill for open mill mixing both black and color compounds.

Packaging

Most of our production is packed as a "wig-wagged" continuous strip cut from 1 ½" to 12" wide (color) or 18" wide (black). We can also cut slabs 36 inches long. Normal strip thickness is 1/4" to 1/2". Compounds are treated with release dip to prevent sticking and packaged in a cardboard "gaylord" box. If you need different packaging, please contact us.

Laboratory Facilities

Our Cuyahoga Falls plant contains two labs – 1) Quality Control Lab for testing specification parameters on production compounds, and 2) a Development Lab with bench scale equipment. We contract with a local advanced outside laboratory for advanced microscopic and analytical work.

Incoming Material

We buy raw materials for two production facilities. All incoming raw materials are bar coded with date and lot number information during receiving. Our check weigh systems require the recording of bar coded information and insure that materials are accurately weighed, and not past shelf life.

FDA and Medical Grade Compounds

FDA and medical grade compliant compounds are available.

Personnel

Polymerics takes pride in providing personal service from top to bottom in our organization. Our staff is readily accessible to directly address your needs.

- Applications

- Molding

- Injection

- Compression

- Transfer

- Extrusion

- Salt bath (LCM)

- Hot air

- Microwave

- Heated solid media

- Calender lines

- Autoclave cure

- Steam cure

- Hot air cure

- Roll building machines

- Standard Compliance

- Meets ASTM D2000

- General Motors

- Ford

- Chrysler

- Military Specifications

- Customer Designed

- Product Offering

- Black or Color

- Straining Capabilities

- Slab, Strip, or Pellet forms

- available

- Working Polymers

- Natural Rubber/Polyisoprene (NR/IR)

- Chloroprene Rubber (CR)

- Butyl Rubber (halogenated and non-halogenated)

- Polyacrylate Rubber (ACM)

- Nitrile Rubber (NBR, NBR/PVC, XNBR and HNBR)

- Styrene Butadiene Rubber (SBR)

- Ethylene Propylene Rubber (EPDM)

- Millable Gum Polyurethane Rubber (PU)

- Polybutadiene (BR)

- Chlorosulfonated Polyethylene (Hypalon)

- Chlorinated Polyethylene (CPE)

- Epichlorohydrin (ECO)

- Vamac (AEM)

- Inquire for additional polymers