Polymerics Custom Mixing

Polymerics is your personal compound and chemical supplier!

We pride ourselves on experience, technology, and personal response.

"I need a compound that meets certain requirements and do not have

a formulation"

If you need a new compound developed from scratch, then you have come to the right place! Polymerics specializes in developing new compound formulations to meet your product and processing requirements, and we do so with a vast knowledge of both testing and raw material implications.

We begin by discussing your specific compound needs. We will accept as much information as you can provide, and ask pertinent questions regarding your process and product needs. With a good understanding of the task at hand, our technical staff will proceed with creating a new formulation in our Development Lab. We have a vast amount of compounding experience to draw from for most types of compounds and applications. Our technical staff may consult further with you as needed as the project proceeds. With "state-of-the-art" technology and a knowledge of a wide range of raw materials, Polymerics will design a compound that fits your technical needs at optimum cost. We keep you informed during the development process and continue to seek your input.

Once the compound is designed, we create a bench scale batch to examine the new compound's mixing characteristics. We then test the compound to form a physical testing profile. When we are satisfied with our bench scale work, we will issue a quotation for your review. The next step is an initial full scale production batch with subsequent processing at your facility. Provided the compound processes and performs as we projected, we will move to full scale production. It is normal at this point to make small compound adjustments to suit your specific processing parameters.

Fill out my online form.

- Applications

- Molding

- Injection

- Compression

- Transfer

- Extrusion

- Salt bath (LCM)

- Hot air

- Microwave

- Heated solid media

- Calender lines

- Autoclave cure

- Steam cure

- Hot air cure

- Roll building machines

- Standard Compliance

- Meets ASTM D2000

- General Motors

- Ford

- Chrysler

- Military Specifications

- Customer Designed

- Product Offering

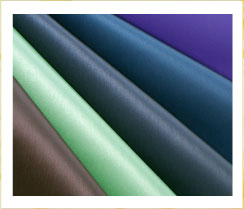

- Black or Color

- Straining Capabilities

- Slab, Strip, or Pellet forms

- available

- Working Polymers

- Natural Rubber/Polyisoprene (NR/IR)

- Chloroprene Rubber (CR)

- Butyl Rubber (halogenated and non-halogenated)

- Polyacrylate Rubber (ACM)

- Nitrile Rubber (NBR, NBR/PVC, XNBR and HNBR)

- Styrene Butadiene Rubber (SBR)

- Ethylene Propylene Rubber (EPDM)

- Millable Gum Polyurethane Rubber (PU)

- Polybutadiene (BR)

- Chlorosulfonated Polyethylene (Hypalon)

- Chlorinated Polyethylene (CPE)

- Epichlorohydrin (ECO)

- Vamac (AEM)

- Inquire for additional polymers

Hypalon is a registered tradename of DuPont Performance Elastomers. This product is no longer produced by DuPont.